Debossing

What Is Debossing?

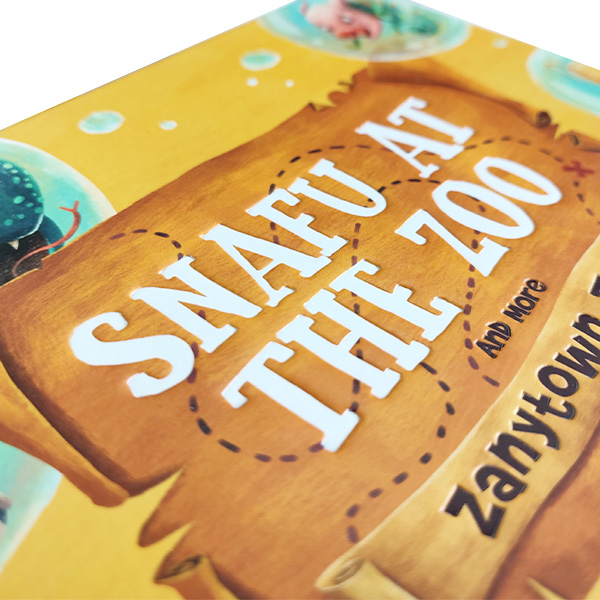

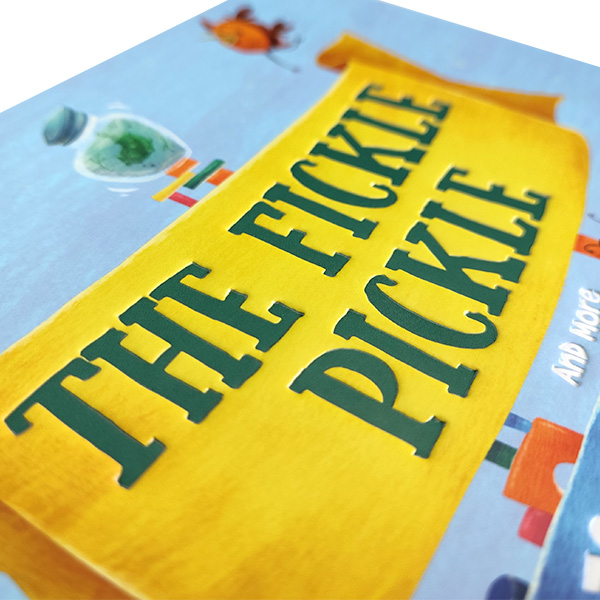

Debossing is a mechanical process by which we impress a design—either lettering, graphics, or both—into the surface of a printed sheet. First, we make a metal mold of your design called a “die”, which we then press into the sheet using a special machine. The result is a powerful three-dimensional effect of a perfect indentation, in the shape of your design, into the paper surface. The process works best on smoother surfaces and so we don’t recommend it for textured paper, but we can apply it successfully to most printed substrates. Debossing is only effective either on paper which is at least 250 gsm or wrapped first onto a grayboard substrate. Debossing can be a single effect in its own right, or you can combine it with printed images or text. You can also combine it with other finishing techniques—such as foil stamping—for a truly superlative effect.

The Advantages of Debossing

Debossing has the potential to impress your customers and elevate your products, but whether it’s the best option for your design will be influenced by the product style, the market for which it’s intended, and your available budget. With that in mind, let’s list the principal advantages of debossing to help you come to the best decision for your project.

- Debossing is an eye-catching design feature which distinguishes your print product from the run-of-the-mill, communicating artistic flair and high quality.

- While instantly effective in its own right, debossing combines well with inking, foil stamping, UV spot coating and other special features.

- Debossing on its own is a relatively economical effect compared to, say, foil stamping, although it has a high impact.

- It adds significant perceived value to your product, making it more likely to be kept, treasured, enjoyed, and shared.

- Debossing gives your printed materials a sophisticated look and helps draw attention to your brand identity.

These are just a few of the advantages of debossing, which make it a desirable choice for products aimed at the upper end of the market, from books and catalogs to deluxe board games, custom paper boxes, and more.

Popular Applications for Debossing

We can apply debossing successfully to many print products. It lends class and style to those products and positions them in the higher end of the market. So, let’s see what impact it has on the appearance of several popular printed products.

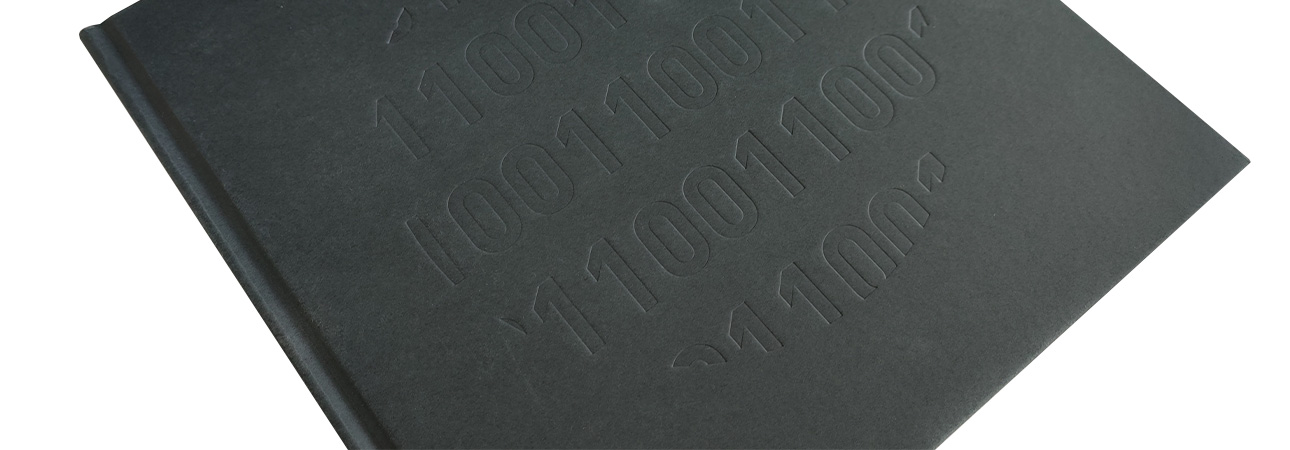

- Art books—art books are works of art in their own right and are all about a display of artistic merit and individual flair. The current trend is for a kind of minimalism in cover design, such as a pearl white matte cover paper with a debossed title. Well-designed debossing on the cover seduces the viewer’s eyes and suggests a sophisticated appeal, setting the book apart from the competition.

- Hardcover books—debossing is a popular choice for hardcovers. Only remember that the cover paper must be at least 250 gsm and wrapped on a grayboard substrate for debossing to be effective.

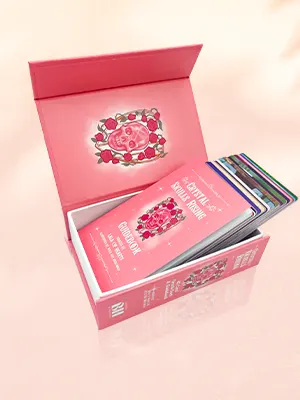

- Rigid boxes—another popular way to use debossing is on the outer surface of luxury custom rigid boxes. Special touches such as debossing lift your box beyond a mere packaging solution and align it with the aspirations of your customers and the quality of your products. It also lends both grace and authority to your brand name and logo.

- Deluxe board games—At the luxury end of the market are deluxe board games made with the finest materials and created to appeal to the wealthiest consumers. For a deluxe edition of any game, adding debossing to the box creates the sophisticated presentation the market demands.

We hope the above examples will help you appreciate the special qualities of debossing and its appeal. It’s a powerful but relatively cost-effective option, and if you focus on the luxury market, it will probably give you an excellent return on your investment.

Debossing Artwork Tips

To get the best results from debossing, it’s important to understand how to prepare the finished digital files for correct printing. You must account for bleed, for example, and make sure that you’ve set the resolution and the color space correctly. So, here are a few helpful tips to guide you when you’re preparing your digital files for debossing.

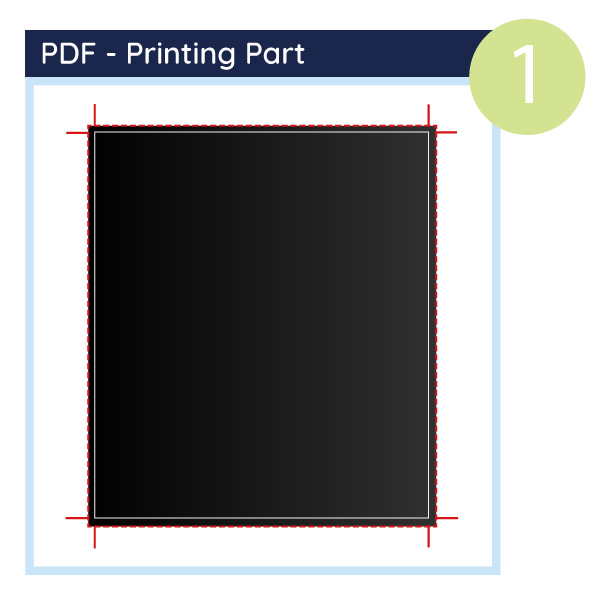

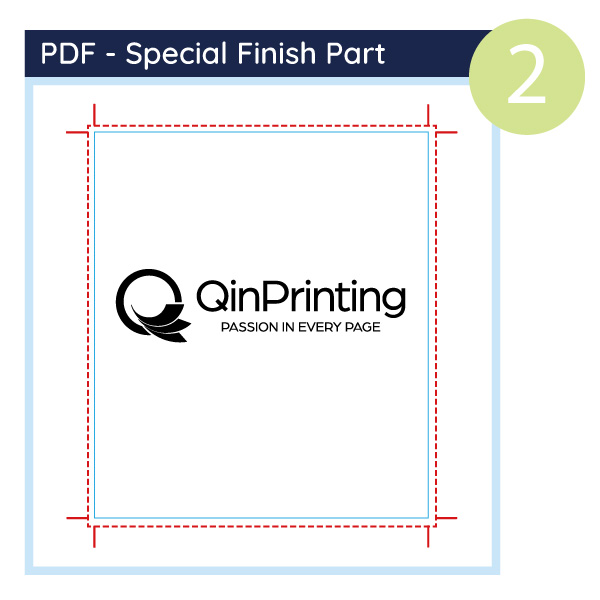

- Setting up your artwork for any special finishes that only affect specific areas, like debossing, requires a separate file called a mask. This type of file allows you to specify exactly where you want the finish, using black to signify which areas should be debossed and white to specify which areas should not. The mask file and your debossing artwork file make up your overall project.

- The easiest way to create a mask file involves using a copy of your artwork file. Once you make a copy of your artwork file, remove all elements from the file that you do not want to be debossed. Then, change the color of all other elements to black. In a CMYK color layout, you generate black using the following formula: C0, M0, Y0, K100. Finally, you need to make sure the deboss printing file is a vectorial file and not a raster.

- When creating your mask file, always make sure that the alignment of the mask file and artwork file are exactly the same. This includes the overall size of the files and the positioning of all shared elements.

- Set up your graphics as vectors in PDF format for the best results. Our recommended software option is Adobe Illustrator.

- Also, make sure that all text to be debossed is at least 14pt and ideally larger if possible.

If you’re working with a professional designer to prepare your files, they should be competent to get everything ready for debossing. But if you’re unsure of anything, please talk to us. We’ll be happy to explain what’s needed step-by-step, liaise with your designer when necessary, and manually check everything ourselves to make sure it all goes smoothly and you end up with a perfect debossing effect. If we discover any errors, we’ll let you know, explain what the problems are, and help you fix them.

Need More Help? Talk to Us!

Deciding to apply debossing is an important decision which changes the appearance and quality of your finished printed product, the design process, and the cost. If you’re not sure about whether it’s right for you, the best thing to do is to talk to us. With over 25 years’ experience under our belts, the latest offset printing technology at our fingertips, a vast knowledge about paper, coatings and finishes of all kinds, and a genuine commitment to customer service, we’ll be happy to give you the best advice to help you choose the perfect solution for both your print project and your budget. Get in touch today for an informal chat or a no-obligation quote. We can’t wait to work with you!