Reverse Tuck End Box

We introduce the structural and style characteristics of reverse tuck end boxes and explore their best uses in retail

What Is a Reverse Tuck End Box?

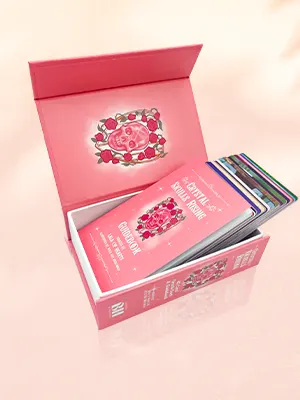

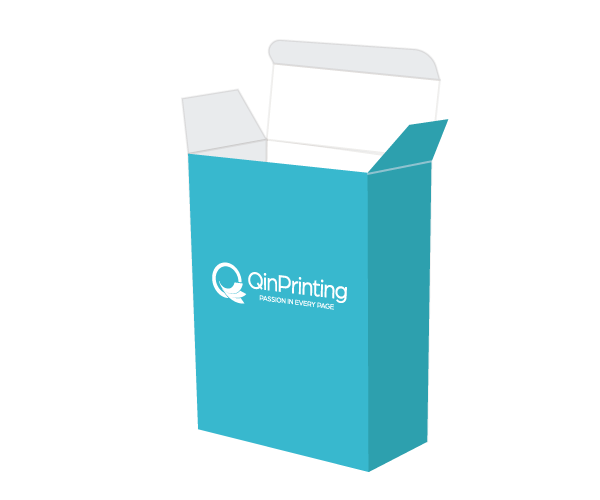

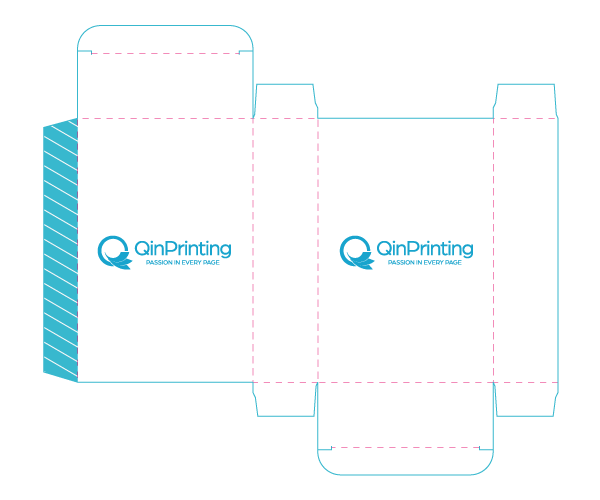

The reverse tuck end box is a fantastic retail packaging solution if you need a box that’s ready for the shelf. Fully customizable and brandable, it creates an attractive presentation for your products. The box comes with a closure at the top that tucks in from rear to front and one closure at the bottom that tucks in from front to rear. It’s super-easy to open and shut and makes an ideal option for retail product boxes.

Structural and Style Features of Reverse Tuck End Boxes

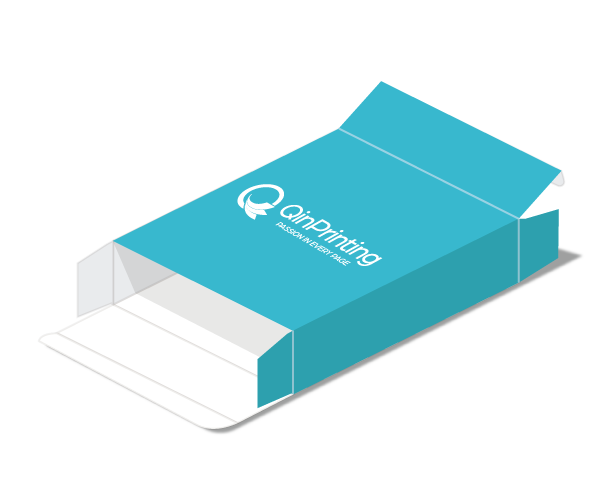

Reverse tuck end boxes are designed on a single sheet of card, paperboard, or corrugated board—typically 250 to 350 gsm C1S paperboard or E-corrugated cardboard —which we print with your custom artwork and text, before die-cutting, folding, and gluing to make the final carton. You can choose to print on both sides or only one side of the box as you prefer. We can provide them pre-assembled or flat-packed for storage and self-assembly. We can further customize your box with extra cut outs, windows, and locks. If you’d like to add a custom insert to your box to hold your products in a snug fit, we can do that, too.

Which Products Are Best Suited to Reverse Tuck End Boxes?

Reverse tuck end boxes are an ideal solution for packaging smaller, lightweight items but as can also support slightly heavier items without risk of inadvertent opening or splitting. The direction of the tuck ends is reversed on each side. They’re popular for cosmetics, pharmaceuticals, candles, and small-scale electronics.

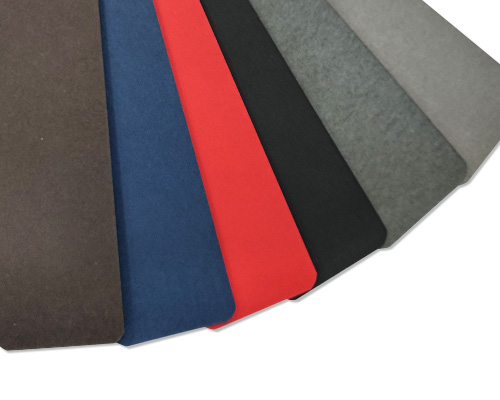

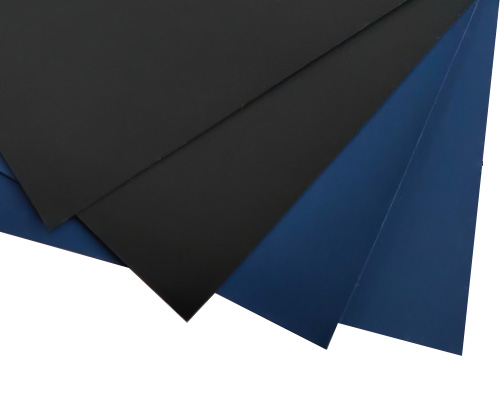

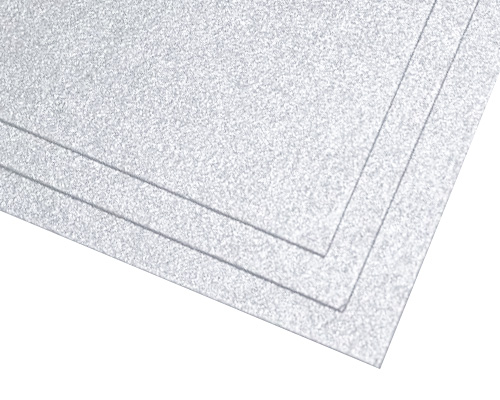

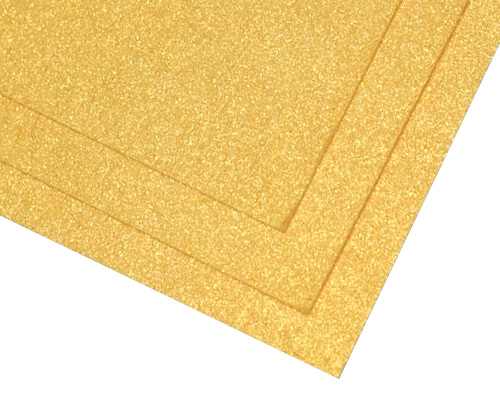

Reverse Tuck End Box Material Options

Reverse tuck end boxes are normally made of either C1S (coated one side) paper, Kraft paper, colored paperboard, or corrugated cardboard. Usually, the coated one side paper weight ranges from 250 gsm to 400 gsm. If you choose to make a corrugated box, we’ll use either E-corrugated cardboard or F-corrugated cardboard, depending on your needs and specifications. All of these materials are suitable for the structural needs of a reverse tuck end box. Which you choose depends on your design needs and your budget. Cardboard is stronger and more rigid than paper, but paper may be better for full-color printing and customization. We can finish the surface of your boxes with lamination, UV spot coating, varnish, foil stamping, and several other special treatments.

Talk to Us!

If there’s anything else you’d like to know about reverse tuck end boxes — or you have questions about the suitability of this solution for your product range — just get in touch. One of our experts will be delighted to talk you through the options and possibilities and can give you a quote should you be interested in taking things further. You can contact us either by telephone, email, Skype, the live chat, or the online contact form. We can’t wait to hear from you!